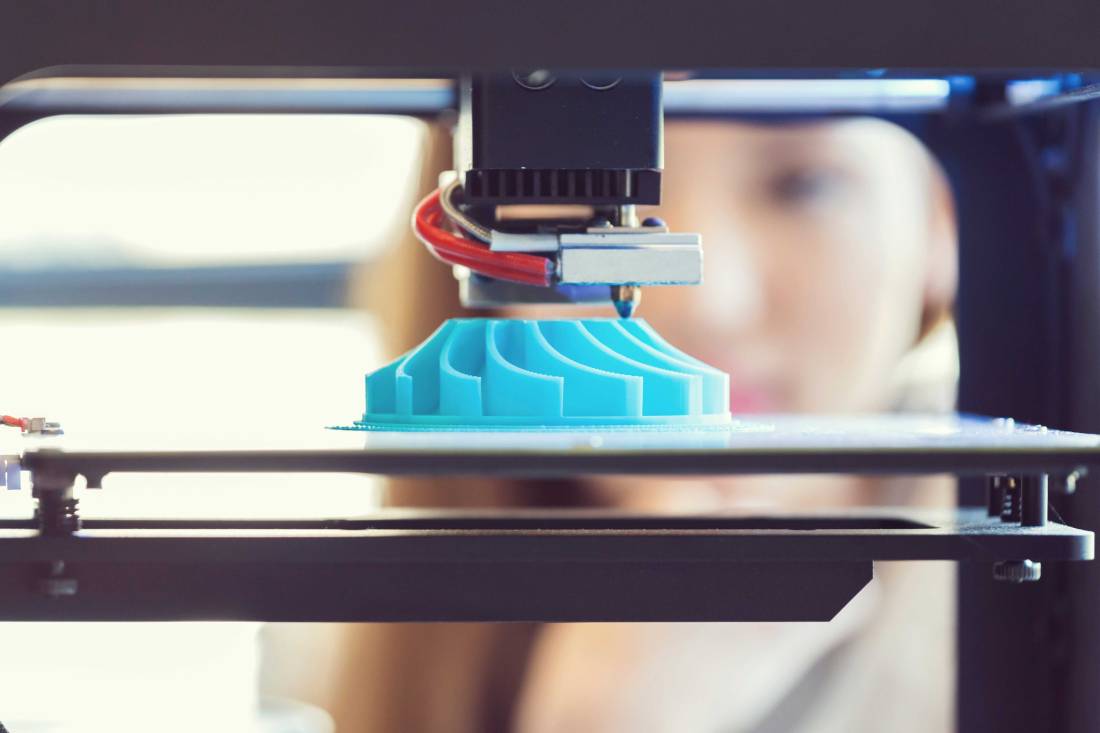

Within the world of production technology, 3D printing (also known as additive manufacturing) provides manufacturers a huge opportunity for increases in efficiency, speed, and manufacturability. As the 3D printing industry continues to expand, designers and engineers are beginning to see a wider variety of materials available for new product implementation, including advanced thermoplastics like PEEK and Ultem®. 3D printing production techniques like fusion deposition modeling (FDM), stereolithography (SLA), or selective laser sintering (SLS) provide the lowest average time between failures and increase the “up-time”, or the time when machines are in operation.

Here are 5 benefits for using 3D printing to produce your next part.

- Speed-to-market: 3D printing allows innovation to develop faster than traditional production techniques due to a shortened development cycle. Compressed lead times that are days instead of months prove invaluable for companies seeking to stay ahead of the competition.

- Cost reduction: Developing injection mold tools or programming are expensive upfront investments. 3D printing processes provide companies the opportunity to produce complex components at a fraction of the cost of using traditional manufacturing techniques.

- Risk Mitigation: Verifying production designs before investing in any tooling generates massive cost and time savings for any company. Prototyping a component using 3D printing allows companies to see a completed model prior to moving forward with investment in full production. Additionally, having a 3D component in hand allows manufacturing designers and engineers to easily visualize the appropriate next steps in a production workflow.

- Communicate Your Vision: Sometimes a blueprint or CAD file isn’t enough to present the vision for a given part. In that case, 3D printing provides the ammunition for engineers and designers to effectively communicate the vision for their design using a 3D model. This allows for immediate feedback and limits ambiguity through an exact, or at least an extremely close representation of the final part.

- Accelerate the Discovery Phase: Testing ideas quickly allows designers and engineers to discover what aspects of a given component work or doesn’t work. Failing fast allows for faster iteration, improving the time between prototype and production.

Learn more about Roncelli Plastics 3D Printing capabilities or request a 3D Printing Quote using the link below.

{{cta(‘7063ba69-9ddc-4f6a-a75f-7f39ea1275cd’)}}