industries

WE SERVE

Roncelli Plastics is a leading provider of precision machined plastic components for mission critical applications in the Aerospace, Space, Defense, Semiconductor, Medical & Life Science, Oil & Gas, and Renewable Energy industries. Our ‘ experienced team of engineers, planners, and machinists provide cost savings, process efficiencies, and optimal part performance for every industry application.

Commercial Aerospace

Roncelli Plastics’ AS 9100 certified manufacturing facilities provide precision plastic manufacturing, efficient turnaround times, and an industry leading commitment to customer service. Roncelli Plastics offers machined plastic components for the commercial, space, and defense aerospace industries, from avionic housings to valve seals and anything in between. Roncelli’s experienced team of Application Development Engineers, Planners, Quality Engineers, and Machinists work closely with every customer, regardless of their size, to ensure we consistently exceed customer expectations.

For over 50 years, Roncelli Plastics has provided solutions for the unique challenges within the aerospace industry. Aerospace customers benefit from material options that meet growing demands for weight reduction, design flexibility, lower manufacturing costs, increased chemical and corrosion resistance, and uncompromising measures for flame smoke toxicity (FST) requirements.

Whether it be aviation system technologies, cabin interiors, exterior structures, or propulsion applications, Roncelli Plastics has the manufacturing and product development expertise to support component requirements in the commercial aerospace sector.

Blank

Typical Applications

- Interiors:

- Brackets

- Handles

- Frames

- Gaskets

- Propulsion

- High temperature bushings

- Thermoal Insulators

- Valve Seals

- Gaskets

- Bearings

- Structural

- Landing Gear

- Braking Systems

- Actuator Systems

Typical Materials

- Celazole® (PBI)

- Delrin® (POM)

- PEEK

- Torlon® (PAI)

- Teflon® (PTFE)

- Ultem® (PEI)

- Vespel®

Space & Defense

Roncelli Plastics has almost 50 years’ experience working with NASA and commercial space contractors to overcome challenges such as extreme thermal shifts, low out-gassing requirements, and reduced launch weight. The material and fabrication expertise developed over this time allows Roncelli Plastics to ensure mission success for customers in the Space industry.

Roncelli Plastics is trusted by the nation’s leading Department of Defense prime contractors to deliver high quality machined plastic components for mission critical requirements. In order to best support the War Fighter, Roncelli has also implemented best in class Foreign Object Debris (FOD) prevention program to ensure product quality.

Blank

Typical Applications

- Brackets

- Bump Stop

- Bushings

- Gears

- Manifolds

- Satellite booms

- Skid Plates

- Window Frames

Typical Materials

- ABS

- Nylon® (PA)

- Delrin® (POM)

- Celazole® (PBI)

- G-10

- G-11

- Torlon® (PAI)

- Teflon® (PTFE)

- PEEK

- Polycarbonate (PC)

- Ryton® (PPS)

- Ultem® (PEI)

- Vespel®

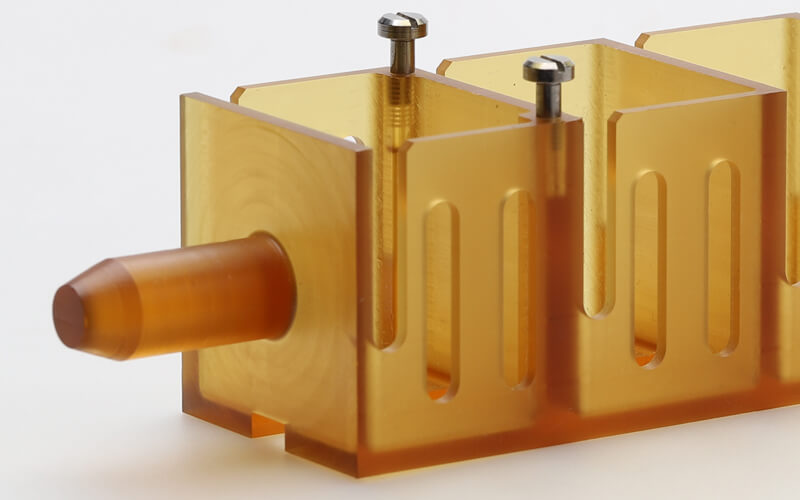

Semiconductor

As a leading provider of precision machining components for the semiconductor industry, Roncelli Plastics manufactures components for ETCH, Wet Process, CMP, and Burn in Testing. Roncelli Plastics’ customers include top semiconductor OEM equipment manufacturers, all of whom benefit from Roncelli’s commitment to exceeding industry standards for quality, cleanliness, and time-sensitive deliverability.

Roncelli Plastics consistently invests in product knowledge and capability improvements in order to streamline efficient precision machining, assembly, and delivery of high quality semiconductor components like wafer grabbers, wafer motion gears, CMP rings, spin chucks, test sockets, hangers, screws, shower heads, and static control applications.

Benefits of Plastic:

- Static dissipative grades

- Chemical resistance

- Low particle generation in bearing and wear applications

- Low outgassing characteristics

- Low levels of extractables when placed in high purity chemicals

- High temperature capabilities

- Electrical insulating properties

- Dimensional stability

- Impact Resistance

Blank

Typical Applications

- Bearings & bushings

- Chemical tanks

- Electrical insulators

- Flexible tubing

- Guards & shields

- General tooling

- CMP rings

- Spin chucks

- Test sockets

- Wafer handling parts

- Wet benches & work stations

Typical Materials

- Delrin® (POM)

- ECTFE

- PET-P

- Ryton® (PPS)

- PEEK

- Ultem® (PEI)

- Celazole® (PBI)

- PVDF

- Vespel®

- Semitron®

- Torlon® (PAI)

Medical & Life Science

Roncelli Plastics’ extensive experience working with USP Class VI certified medical and implantable grade materials like Radel® (PPSU), Ultem® (PEI) and PEEK, allows Roncelli to address a variety of medical & life science component fabrication needs at the ISO-13485 certified production facilities.

Roncelli Plastics’ medical manufacturing expertise allows delivery of precision machined components for applications including implantable devices, surgical instruments, trauma guides, orthopedic & spinal devices. With a rapid prototype manufacturing division that offers access to swiss machines, multi axis mills, precision CNC machining and injection molding centers, Roncelli delivers industry-required accuracy coupled with exceptional on-time delivery.

Blank

Typical Applications

- Spinal Cages

- Orthopedic devices

- Endoscopy

- Fluidics & diagnostic equipment components

- Surgical instruments & handles

- Trauma targets & guides

Typical Materials

- PEEK

- Radel® (PPSU)

- Ryton® (PPS)

- Delrin® (POM)

- Ultem® (PEI)

- Vespel®

Oil & Gas

As a consequence of the growing demand for oil and natural gas across the globe, the oil & gas industry has benefited from the utilization of high performance polymers to facilitate the technological advancements and innovations within the oil-drilling, refining, and distribution processes. Roncelli Plastics provides extensive material application knowledge and machining expertise to the oil & gas industry. The role of plastic machined products continues to gain visibility and support due to its reliability and advantages over metal alternatives.

As demand for oil & gas products continue to grow, Roncelli Plastics recognizes that so do the demands placed upon the operating equipment within the industry. Precision machined plastic components with outstanding physical and chemical properties, in addition to excellent resistances to corrosion, contamination, and deterioration, allow machined and fabricated plastics components the necessary durability to withstand the industry’s harsh environmental conditions.

Blank

Typical Applications

- Bearings

- Seals

- Rings

- Gaskets

- Bushings

Typical Materials

- PEEK

- PVDF

- Ryton® (PPS)

- Torlon® (PAI)

- Ultem® (PEI)

Renewable Energy

As a precision machining expert of high performance polymers, Roncelli Plastics understands the pain points within the renewable energy industry. Polymers must possess strong transmittance in addition UV, environmental, and long term high temperature resistance. Reduced weight, material cost, component lifespan, and overall installation costs allow customers to benefit from implementing polymer solutions.

Blank

Typical Applications

- Bushings

- Friction Pads

- Gaskets

- Grippers

- Liners

- Rings

- Seals

- Sliding Ring Segments

- Spacers

- Wear pucks

- Wafer holders

Typical Materials

- PEEK

- PVDF

- Ryton® (PPS)

- Torlon® (PAI)

- Ultem® (PEI)

get started

CERTIFICATIONS

TERMS & CONDITIONS

NAVIGATION

RONCELLI NEWS

RONCELLI MEDICAL