materials

Whether you’re searching for commodity plastics, high performance polymers, engineering-grade thermoplastics, or anything in between, Roncelli Plastics’ material expertise serves as an invaluable guide to determine the best resource for any application.

Need help choosing a material?

The experts at Roncelli are very knowledgable and can help you find exactly what you are looking for.

PEEK

PEEK (polyetheretherketone) is a high performance engineering plastic. PEEK exhibits excellent chemical resistances, rigidity at high temperatures, as well as excellent mechanical strength and dimensional stability. PEEK applications span multiple industries including aerospace, semiconductor, oil & gas, and medical.

Blank

Family of Materials

- PEEK 1000IM

- PEEK GF30

- PEEK CA30

- PEEK LSG

- PEEK HPV

- TECA PEEK

Typical Uses

- Back Up Rings

- Bearings

- Bushings

- Dental Instruments

- Seals

- Surgical Instruments and handles

- Trays

- Vacuum Wand Handles

Vespel®

One of the highest performing thermoplastics available on the market, Vespel® can continuously operate from cryogenic temperatures to extreme elevated temperatures up to 900°F in spurts.

Bearing grade Vespel® will successfully operate without lubrication …

Blank

Further Material Description

in many high load, high speed, and/or high temperature environments where most other thermoplastic and metal bearings may fail.

For applications requiring low wear and long lifespans in extreme environments, Vespel® exhibits superior performance. Vespel’s extremely low outgassing, radiation resistance, and dimensionally stability make it optimal for Space applications.

Family of Materials

- Vespel® Polyimide CR-6100

- Vespel® Polyimide 6110

- Vespel® Polyimide SCP 5050

- Vespel® Polyimide SP-1 Unfilled

- Vespel® Polyimide SP-3 15% MoS2 Filled

- Vespel® Polyimide Sp-21 15% Graphite Filled

- Vespel® Polyimide SP-211 Graphite PTFE

- Vespel® Polyimide SCP 5009 Bearing & Grade

- Vespel® Polyimide 50094 LOw Graphite Filled Grade

Typical Uses

- Bushings and Bearings

- Flanged Bearings

- Plungers

- Printer Wire Guides

- Rotary Seal Rings

- Spline Couplings

- Thrust Washers and Discs

- Valve Seals

- Wear Strips

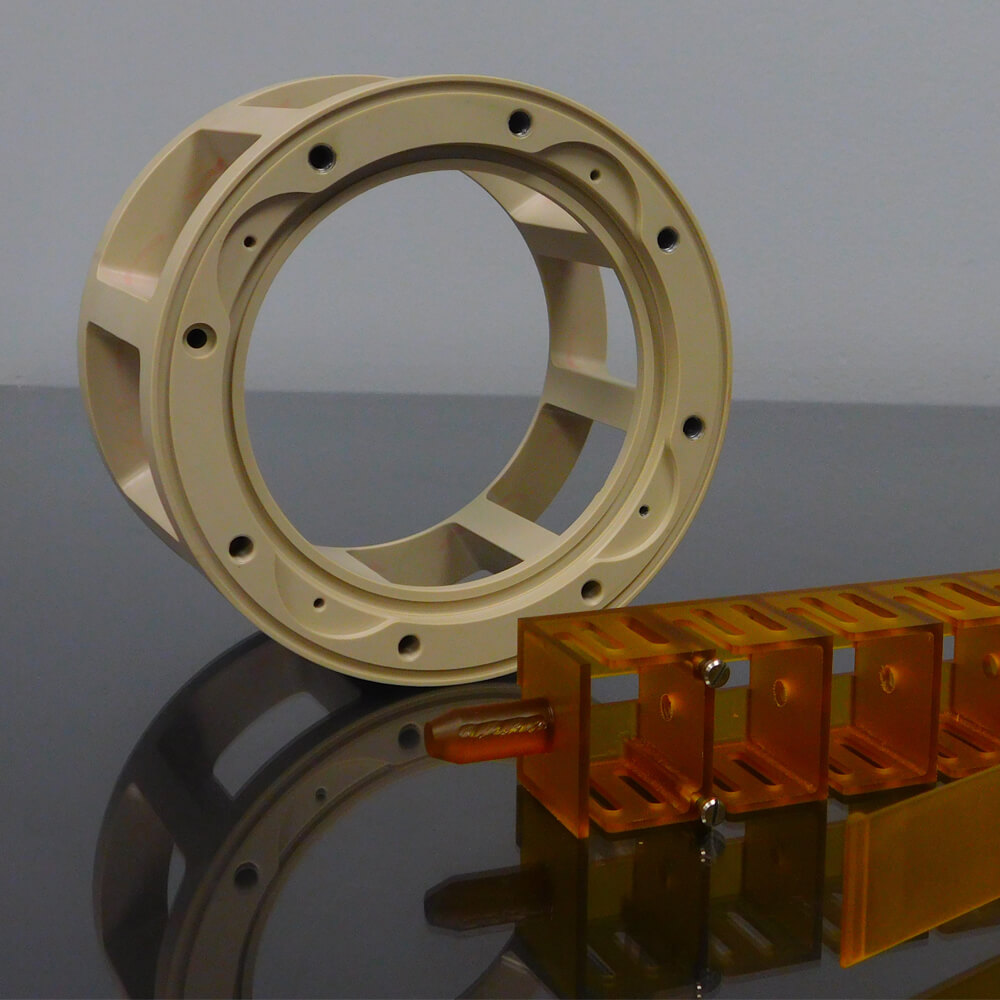

Ultem® (PEI)

Ultem® (polyetherimide) contains extremely high dielectric strength, easy machinability, excellent dimensional stability, and excellent thermal resistance. Ultem® can also withstand repeated sterilization cycles in a steam autoclave, making FDA compliant grades available for use in the Medical & Life Science industries.

Blank

Family of Materials

- ULTEM 1000 Unfilled

- ULTEM 2100 10% Glass Filled

- ULTEM 2200 20% Glass Filled

- ULTEM 2300 30% Glass Filled

Typical Uses

- Medical instrument components

- Scientific equipment parts

- Manifolds

- Electric connectors

- Electrical insulation parts

- Semiconductor equipment components

- Chip test sockets

Torlon® (PAI)

Torlon® (PAI) (polyamide-imide) is an extremely strong and stiff advanced engineering polymer that is often used in elevated temperature environments where alternative thermoplastics would lose their mechanical properties.

Blank

Further Material Description

Outstanding bearing grade, resistance to common solvents and acids, and excellent electrical grade make PAI and optimal choice for use in the semiconductor industry.

Family of Materials

- Torlon® PAI 4203 Electrical Grade PAI Extruded

- Torlon® PAI 4275 Bearing Grade PAI Extruded

- Torlon® PAI 4301 Bearing Grade PAI Extruded

- Torlon® PAI 4435 Bearing Grade PAI Extruded

- Torlon® PAI 4540 Bearing Grade Extruded

- Torlon® PAI 5030 Glass Filled Extruded

- Torlon® PAI 5530 Glass Filled Compression Molded

- Torlon® PAI 7130 Carbon Filled

- Torlon® PAI 7530 Carbon Filled

Typical Uses

- Bushings and Bearings

- Insulators and Electrical Connectors

- Seals

- Wear Rings

- Bearing Cages

- Rotating Equipment Components

- Semiconductor Parts (Burn In Test Sockets)

- Structural Parts

Ryton® (PPS)

Often used as an alternative to PEEK when used in moderate temperatures, Ryton® (PPS) contains outstanding chemical resistance, superior heat and steam resistance, good dimensional stability, and high dielectric strength.

Blank

Family of Materials

- PPS Bearing Grade

- PPS Glass Filled

- HPV

Typical Uses

- Retaining Rings

- Polymer Vanes for Pump and Compressor Applications

- Polymer Pistons

- Thrust Washers

- Scroll Tip Seals

- Bushings

- Wear Surfaces

- Fuel Pipe

- Brackets

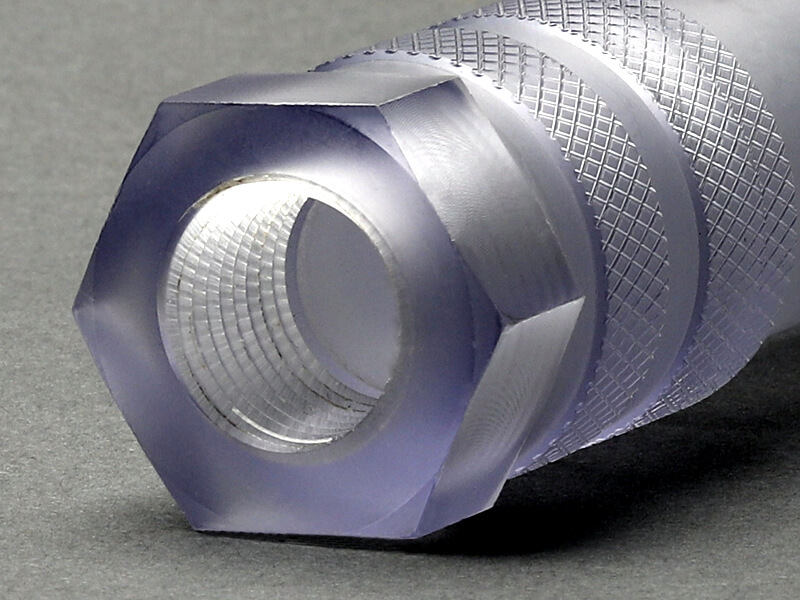

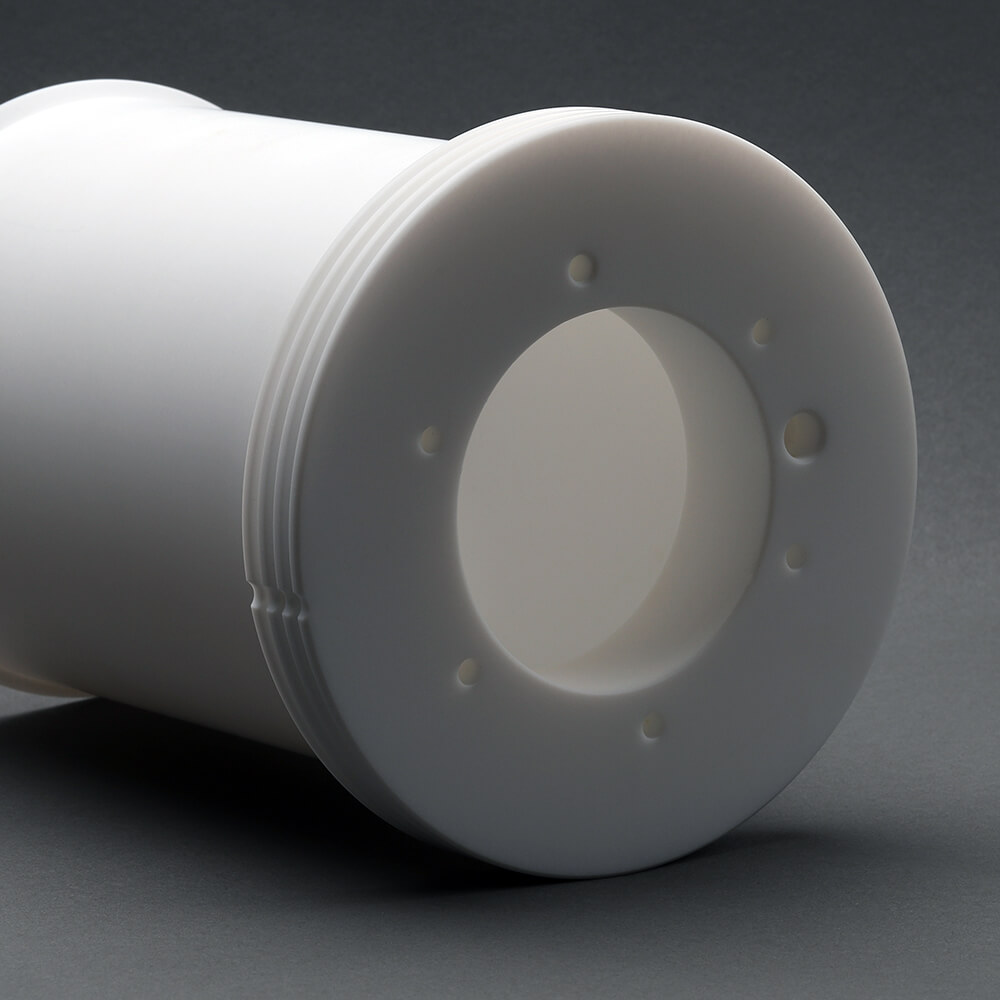

Teflon® (PTFE)

Teflon® (PTFE) (polytetrafluoroethylene) is a soft, low friction polymer containing outstanding chemical and weathering resistances. With the ability to perform well at elevated temperatures, Teflon® is a great choice for bearing grade applications. Teflon® has excellent electrical insulating properties which allows it to also be used in electric applications.

Blank

Family of Materials

- Fluorosint 500

- Fluorosint 207

- Fluorosint HPV

- Fluorosint MT-01

- Fluorosint 135

Typical Uses

- Bearings

- Electrical insulation

- Sealing Applications

- Wear Applications

Delrin® (Acetal)

Delrin®, also known as Acetal (POM) (polyoxymethylene) is an engineering plastic exhibiting high strength, low friction, and excellent wear properties in wet & dry environments. For applications that require complex or tight tolerances, acetal is a reliable selection due to its great machinability.

Blank

Family of Materials

- Acetron GP

- Acetron MD

- Delrin Acetal

- Delrin AF Blend

- Delrin AF 100

Typical Uses

- Bearing blocks

- Belt guide bushings

- Pump and valve parts

- Manifolds

- Gears

- Wear pads

- Jigs and fixtures

PCTFE

PCTFE (polychlorotrifluoroethylene) is a fluorocarbon polymer, that exhibits a distinct combination of physical and mechanical properties including chemical resistance, near zero moisture absorption, excellent electrical and flammability properties. Additionally, PCTFE has a useful temperature range of -400°F to 400°F while also containing extremely low outgassing, making PCTFE common in aerospace applications.

Blank

Family of Materials

- Sample

- Sample

Typical Uses

- Die Pads

- Food processing and equipment parts

- Hinges

- Impact Pads

- Light duty chain guides

- Orthotic and prosthetic devices

- Thermoformed material handling devices

- Water Storage

Acrylic (PMMA)

Also known as Plexiglas®, Acrylic is a transparent thermoplastic with outstanding strength, stiffness, and optical clarity.

Arcylic exhibits qualities similar to glass, but with reduced weight and greater impact resistance. A clear plastic, Arcylic is also available in various colors.

Blank

Family of Materials

- Acrylic PMMA Clear

Typical Uses

- Indoor and outdoor signage

- POP displays

- LED lighting panels

- Many more applications.

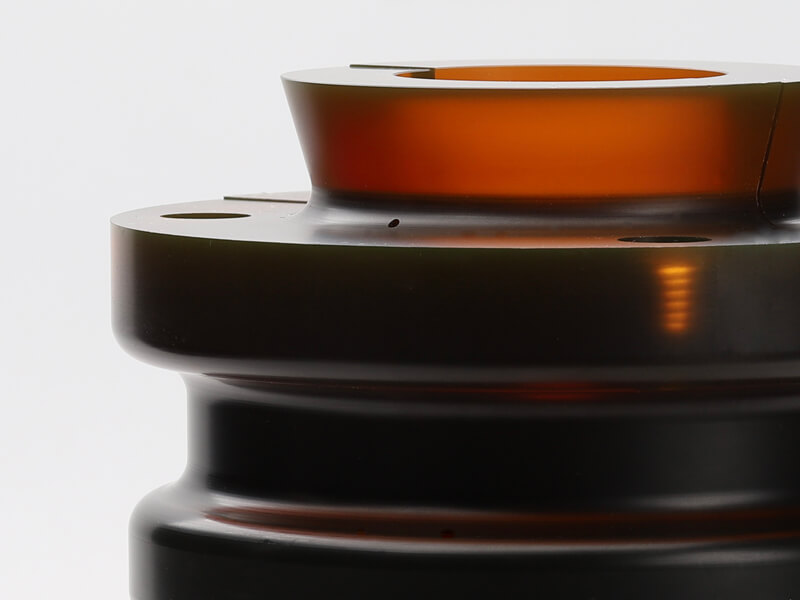

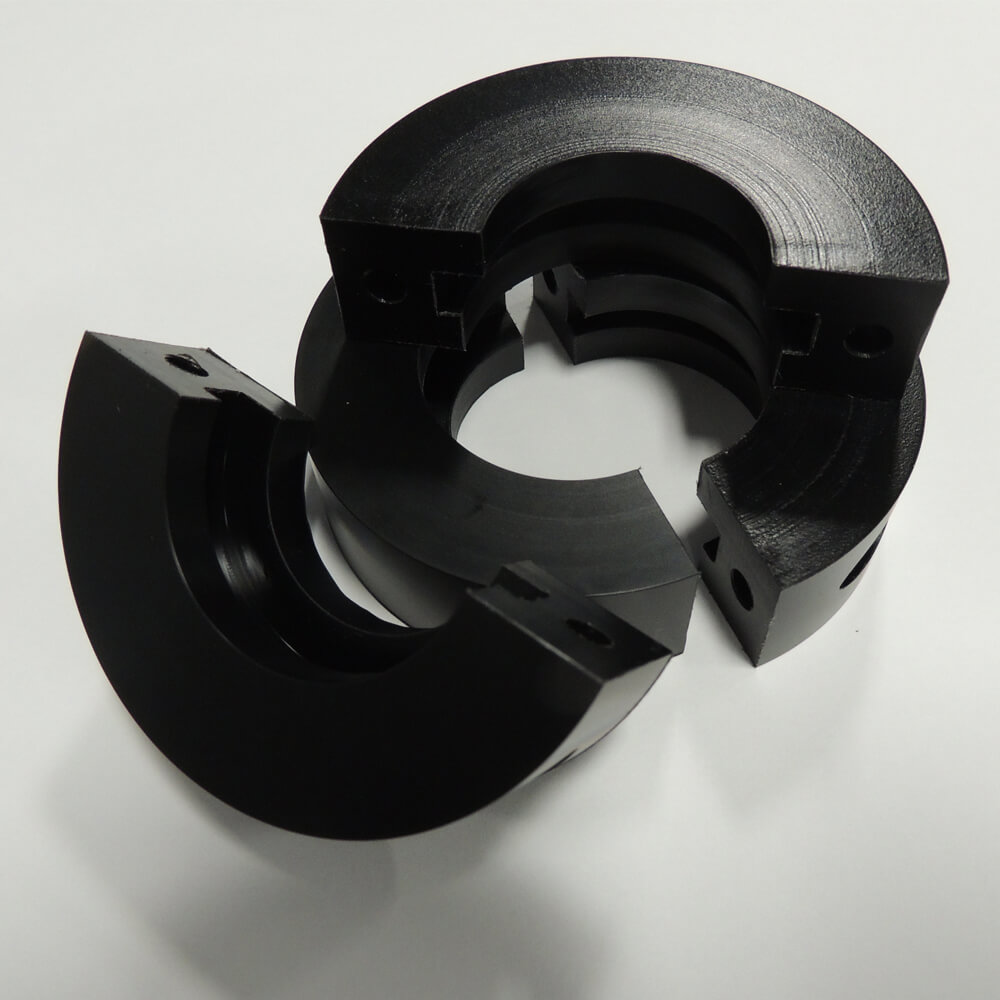

Celazole® (PBI)

Celazole® (PBI) is one of the highest performing thermoplastics available today. Celazole offers the highest mechanical properties of any plastic above 400°F, highest heat deflection temperature at 800°F, lowest coefficient of thermal expansion, and highest compression strength of all unfilled plastics.

Blank

Family of Materials

- Celazole L-60

- Celazole TF-60

- Celazole TK-60

- Celazole TKL-60

- Celazole U-60

Typical Uses

- Ball Valve Seats

- Clamp Rings

- Electrical Connectors

- High Heat Insulator Bushings

- Piston Rings

- Pump Bearings

- Valve Seats

- Wafer Carriers

- Thrust Washers

- Temperature Sensor Housings

- Contact Seals

Noryl® (PPE)

Containing high dielectric strength, a low coefficient of thermal expansion, low moisture absorption, and good dimensional stability make Noryl® an excellent choice for electrical applications. Noryl® is often used as an alternative to Ultem® specifically for applications where high temperature capability is not as necessary.

Blank

Family of Materials

- PPO – Polyphenylene Oxides

- Noryl

Typical Uses

- Automotive Instrument Parts

- Electrical Insulation/Housing

- Surgical Instruments

- Water Pump Components

- Water Softener Valves

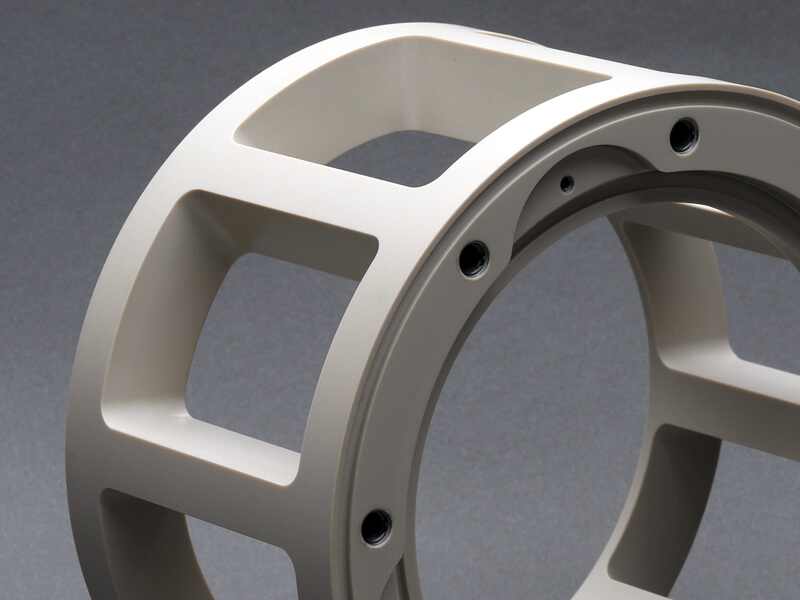

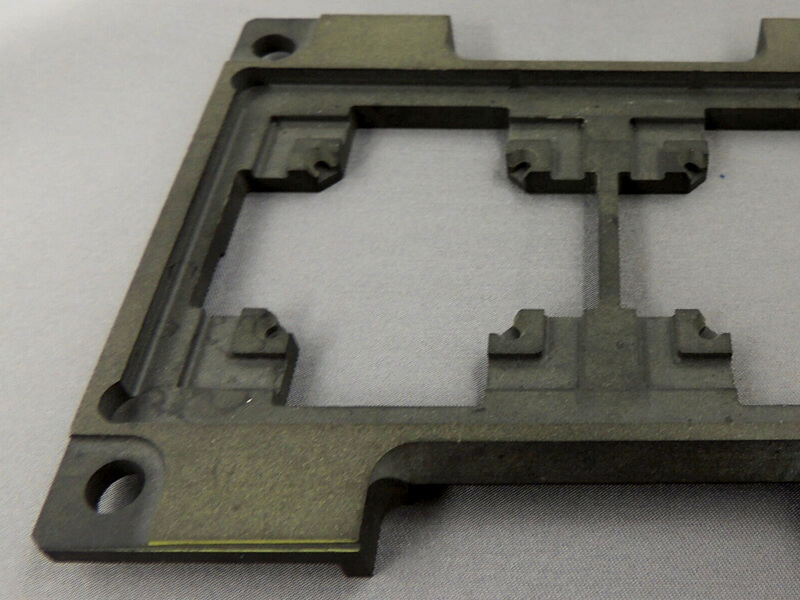

Semitron® MPR 1000

Developed exclusively for the semiconductor industry, there are various useful benefits from Semitron®. This material containe excellent heat resistance, low out-gassing, low rate of erosion, excellent chip resistance, durability, and machinability. Various grades have certain advantages.

Blank

Semitron Material Grades

- Semitron MPR 1000 used for in vacuum chamber applications found in Etch, CVD, and Ion Implant. This grade is one of the lowest cost polymer solution with the best in chamber performance.

- Semitron MPR300 contains very low moisture absorption, exceptional machinability, strength and stiffness that exceed unfilled PEEK materials, and high thermal resistance, Semitron® allows semiconductor manufacturers design flexibility for test sockets.

- Semitron® MDS 100 developed to provide a combination of high strength, stiffness, and low moisture absorption. This material addresses engineering concerns associated with uncontrolled application environments in the semiconductor industry.

Family of Materials

- Semitron MPR 1000

- Semitron MP 370

- Semitron MDS 100

- Semitron ESd 225

- Semitron ESd 410C

- Semitron ESd 420

Typical Uses

- Clamp Rings

- Fixtures for Electronic Testing

- Focus Rings

- Insulators

- Mounting Points

- Pins

- Screws

- Shower Heads

- Structural Parts for Semiconductor Mfg Equipment

- Test Sockets

- Trench Rings

- Vacuum Pads

Polypropylene (PP)

Polypropylene (PP) provides an uncommon combination of outstanding physical, chemical, mechanical, thermal, and electrical properties. Lightweight, heat-resistant, and semi-rigid, is commonly used for vacuum systems where elevated temperatures and high pressures are routinely experienced.

Blank

Family of Materials

- Polypropene

- Polyolefin

- Propylene

Typical Uses

- Automotive

- Consumer Goods

- Pill Containers

- Medical Valves

- Diagnotistic Devices

Polycarbonate (PC)

Polycarbonate (PC) is a strong, transparent, and stiff polymer with superior impact resistance and excellent dimensional stability, even at lower temperatures. Polycarbonate (PC) materials comes in a variety of different grades including general purpose, machine grade, glass-filled, flame inhibiting, superior chemical resistance and abrasion resistant.

Blank

Family of Materials

- PC-300

- PC-350

- PC 10% Glass Filled

- PC 20% Glass Filled

- PC 30% Glass Filled

- PC 40% Glass Filled

- PC Unfilled

Typical Uses

- Biomedical devices

- Electrical Connectors

- Electrical housings

- Insulators

- Machine Guards

- Medical Tubing

- Relay Components

- Semiconductor Applications

- Structural Components

PET-G

A transparent thermoplastic material with good impact resistance, FDA compliance, and outstanding thermoformability. Often used in applications requiring material clarity and durability.

Blank

Family of Materials

- PET-G

- Ertalyte (PET-P)

- HDPE

- LDPE

- PCTFE

Typical Uses

- Die Pads

- Food processing and equipment parts

- Hinges

- Impact Pads

- Light duty chain guides

- Orthotic and prosthetic devices

- Thermoformed material handling devices

- Water Storage

ECTFE

ECTFE (ethylene chlorotrifluoroethylene) contains greater strength, stiffness, abrasion resistance, and creep resistance compared to most other fluoropolymers with high impact strength. Additionally, ECTFE contains strong fire resistance and exceptionally smooth surfaces.

Blank

Family of Materials

- ECTFE

Typical Uses

- Gaskets

- Acid handling

- Mining Applications

- Semiconductor parts (wet tools and tubing systems)

Fluorosint® (mica-filled PTFE)

Fluorosint® capable of being used continuously to temperatures of 500° Compared to traditional PTFE, Fluorosint® has a higher load carrying capability, a lower coefficient of thermal expansion, while maintaining similar chemical resistance.

Blank

Family of Materials

- Fluorosint 500 PTFE

- Fluorosint 207 PTFE

- Fluorosint HPV PTFE

- Fluorosint MT-01

- Fluorosint 135 PTFE

Typical Uses

- Pump and Valve Wear Parts

- High Temp Seals

- Compressor

- Thrust Washers

- Packing Sets

- Piston Rings

Radel® (PPSU)

Radel® (PPSU) (polyphenylsufone) is a high temperature advanced engineering polymer with outstanding impact resistance. Resistant to hydrolysis when exposed to steam or hot water even over repeated sterilization cycles, and its extremely high impact resistance make Radel® (PPSU) a popular choice for the Medical and Life Science industries.

Blank

Family of Materials

- RadelR 5500

- Available in Natural or Various Colors

Typical Uses

- Medical Handles

- Endoscopic surgical devices

- Implant trials

Can't Find the Material You Need?

Let the Roncelli Plastics Material Experts Find It!

CERTIFICATIONS

TERMS & CONDITIONS

NAVIGATION

RONCELLI NEWS

RONCELLI MEDICAL