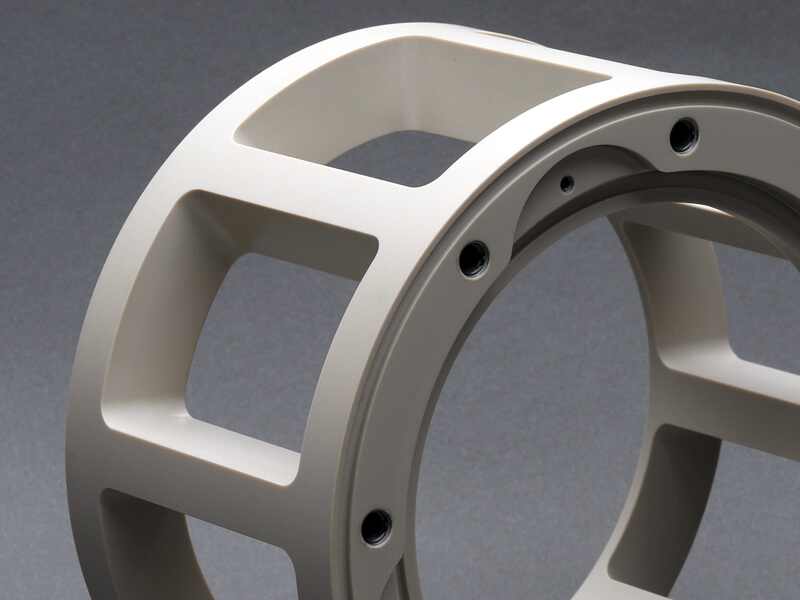

PEEK (Polyetheretherketone)

PEEK is a high temperature wear material with outstanding chemical resistance. Its inherent wear and abrasion resistance and high strength make it an idea material for corrosive and demanding environments. PEEK also has great performance in steam and hot water, and can operate in temperatures to 480o F.

PEEK shapes can be produced by utilizing Extrusion, Injection Molding, or Compression Molding methods. PEEK can also be filled with a variety of materials to enhance its performance.

What are the Benefits of PEEK?

- High Strength

- Toughness

- Excellent Chemical Resistance

- Good performance in Steam

- Outsanding Wear Resistance

- Very good Abrasion Resistance

- FDA, USDA, 3A Dairy, and USP Class VI Compliant

What are the typical applications of PEEK?

Bushings Seals

Wear Bands Nozzles

Spools Rotors

Labyrinth Seals Back Up Rings

Thrust Washers Gears

Impellers Valve Seats

Poppets Insulators

Rollers Pistons

Common Formulations of PEEK:

(Extruded) Unfilled – Chemical Resistance with High Purity

(Extruded) Glass Filled – 30% Glass Fiber Reinforced—Higher Strength and Rigidity

(Extruded) Bearing Grade – Internally Lubricated—Improved Limiting PV and Wear Resistance

(Extruded) Carbon Filled – 30% Carbon Fiber Reinforced—Greater Strength, Stability, and Wear Resistance

(Extruded) High Temperature – Unfilled Purity with improved Heat Deflection Temperature

(Extruded) PTFE Filled – 20% PTFE Reinforced—Lower Coefficient of Friction, Improved Wear Resistance

(Extruded) Ketron® 1000 – Unfilled life science grade PEEK.

(Extruded) Ketron CA30 LSG PEEK – Unfilled life science grade PEEK.

(Extruded) Semitron MP370 – Modified PEEK for improved Stability, and Machinability

(Compression Molded) Unfilled – Chemical Resistance with High Purity in larger shapes

(Compression Molded) Glass Filled – 30% Glass Fiber Reinforced – Higher Strength and Rigidity in larger shapes

(Compression Molded) Bearing Grade – Internally Lubricated – Improved Limiting PV, Wear Resistance in larger shapes

(Compression Molded) Carbon Filled – 30% Carbon Fiber Reinforced – Strength, Stability, Wear Life in larger shapes

(Compression Molded) Semitron® Esd 480 – Electrostatic Dissipative material with low Surface Resistivity

(Compression Molded) Semitron® Esd 490HR – Electrostatic Dissipative material with higher Surface Resistivity

(Compression Molded) Semitron® MDS 100 – High Strength, Rigidity, and Dimensional Stability

Need assistance?

CERTIFICATIONS

TERMS & CONDITIONS

NAVIGATION

RONCELLI NEWS

RONCELLI MEDICAL