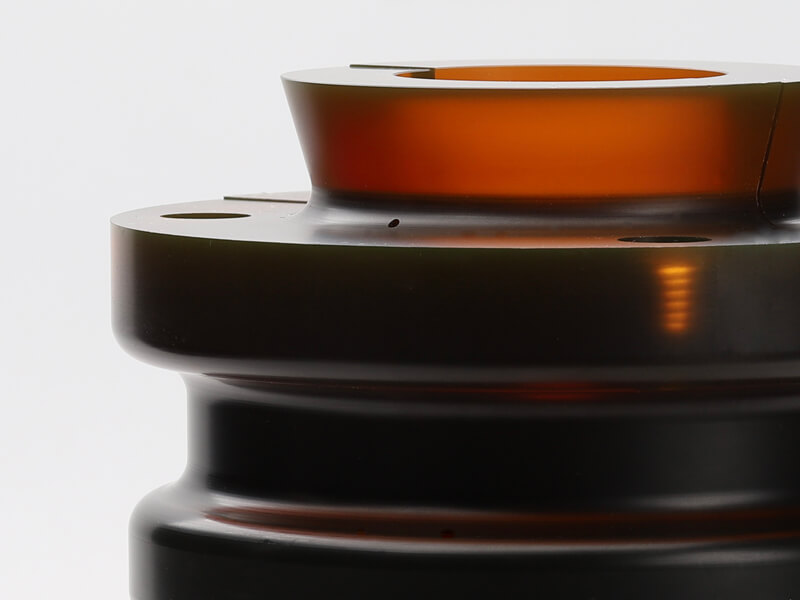

Ultem® (Polyetherimide)

Ultem® is an amorphous material with very good strength and rigidity at elevated temperatures. It has very good resistance to acids and steam, and exhibits good impact resistance. Ultem® has very high Dielectric Strength, and very good Thermal Stability.

Ultem® shapes can be produced by utilizing Extrusion, Injection Molding, and Compression Molding methods. Ultem® can also be filled with various materials to enhance strength, stability, and dielectric properties.

What are the Benefits of Ultem®?:

- High Strength

- Toughness

- Very High Dielectric Strength

- Good performance in Steam

- Creep Resistance

- FDA, USDA, NSF, and USP Class VI Compliant

What are the typical Applications of Ultem®?

Fixtures Adaptors

Test Sockets Connectors

Insulators Plungers

Medical Trays Probes

Instrument Handles Fittings

Pistons Clamps

Nozzles Manifolds

Common Formulations of Ultem®:

Ultem® 1000– Unfilled, High Strength and Toughness, Dielectric Strength

Ultem® 2300 – 30% Glass Filled, Improved Strength and Rigidity

Semitron Esd® 410C – Electrically Conductive

Semitron® Esd 420 – Electro Static Dissipative

Semitron® Esd 420V – Electro Static Dissipative with Improved Strength and Stiffness

Need assistance?

CERTIFICATIONS

TERMS & CONDITIONS

NAVIGATION

RONCELLI NEWS

RONCELLI MEDICAL